Railways keep most industries moving, quite literally. Unloading rail cars in a warehouse setting need to be executed quickly and safely upon arrival, so they are well on their way.

So How Does Spartan Logistics Unload Rail Cars While Reducing Risk and Improving Production?

With a collaboration of Spartan's Warehouse Manager, a local vendor with a national equipment manufacturer account, and a Director of Maintenance at the Spartan corporate level — the overall solution agreed upon was centered almost exclusively around the safety and increased productivity of a high-end rotating clamp truck to unload 2-3 ton paper rolls from rail cars from the Fort Smith, AR rail access warehouse.

Spartan's investment in a new Yale clamp truck equipped with a swivel function, allows the clamp to rotate left and right at an angle to pick up jumbo paper rolls. Paper rolls are highly vulnerable to damage—even from equipment specifically designed to handle them. If you've never spent time in the printing industry, you might assume the biggest challenge in handling 5,000+ lb. paper rolls might be their weight. Not exactly. Too much clamping pressure and the roll can become damaged causing it to go out of shape, impacting productivity and increasing costs. Too little pressure and the roll can slide through or drop out of the clamp.

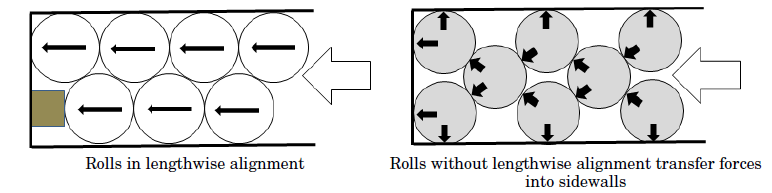

As you can see from the above diagram, depending on how the rolls are loaded, they can shift while in transit. Even the most experienced forklift drivers can have an off day while maneuvering a forklift on a dock plate to unload extremely heavy jumbo rolls.

With the investment of the new Yale “rail car special”, Spartan's Fort Smith warehouse is now equipped with a “swivel” function allowing the clamp to rotate left and right at an angle to pick up rolls; this is a huge time saver and a big risk reducer. As you view the video below, our operator enters the rail car and as you can see, the dock plate he drives over is not much wider than the clamp truck itself; having a clamp that can rotate to get to a roll over a small bridge puts the driver in a much safer and more productive position.

Unloading rail cars used to be a major ordeal but with new equipment designed for the task, our Fort Smith clamp operators have no fear and look forward to receiving rail cars. Previously, one operator could unload two rail cars a shift and now the same operator can unload and place three rail cars per shift.

With the investment of a new Yale clamp truck, the end result is happier, safer employees supporting a high productivity rate in compliance with site safe working practices.

Spartan Logistics’ warehouse locations are near the central part of the U.S., placing them within a one-day truck delivery time to:

- 2/3 of the population of the U.S. and Canada

- 60% of the manufacturing companies in the U.S. and Canada

- Cities such as New York, Chicago, Baltimore, Detroit, Cleveland, and Pittsburgh, as well as most other major cities in the Midwest and on the Eastern Seaboard

- Nearly 3 million square feet of industrial space, or more than 30% of U.S. market and half of the Canadian market

Spartan Logistics is equipped to handle all your contract storage needs including textiles, paper products, food and beverage, glass, automotive supplies, furniture, and more. We’ve been in business for over 30 years, giving us unmatched experience to meet your current, emergency and future storage and distribution needs.

Contact Spartan logistics at (614) 497-1777 to discuss our locations and services further.

Topics: Rise of 3PL Fulfillment Services, Supply Chain Strategy, Logistics News, Warehouses with rail capacity, Logistic Leaders